Scope of Work

Included Every Visit

(Quarterly)

- Replace all MERV 8 filters (custom sizes)

- Confirm cooling/heating function

- Clean condenser coils (outdoor)

- Flush drain lines (as accessible)

- Confirm safe voltage & amp draws

- Take equipment photos + update digital log

- Check for abnormal wear or service needs

Summer & Winter Deep Dive

(Biannual)

- Test: Capacitors, contactors, relays

- Inspect: Wiring, components, connections

- Clean indoor blower compartments (winter)

- Check: Refrigerant charge (subcool/superheat) and temperature splits

- Replace commonly replaced parts (see replace section)

Reporting and

Documentation

- Equipment condition notes and action items

- Photo documentation to support any necessary repairs or deep cleanings

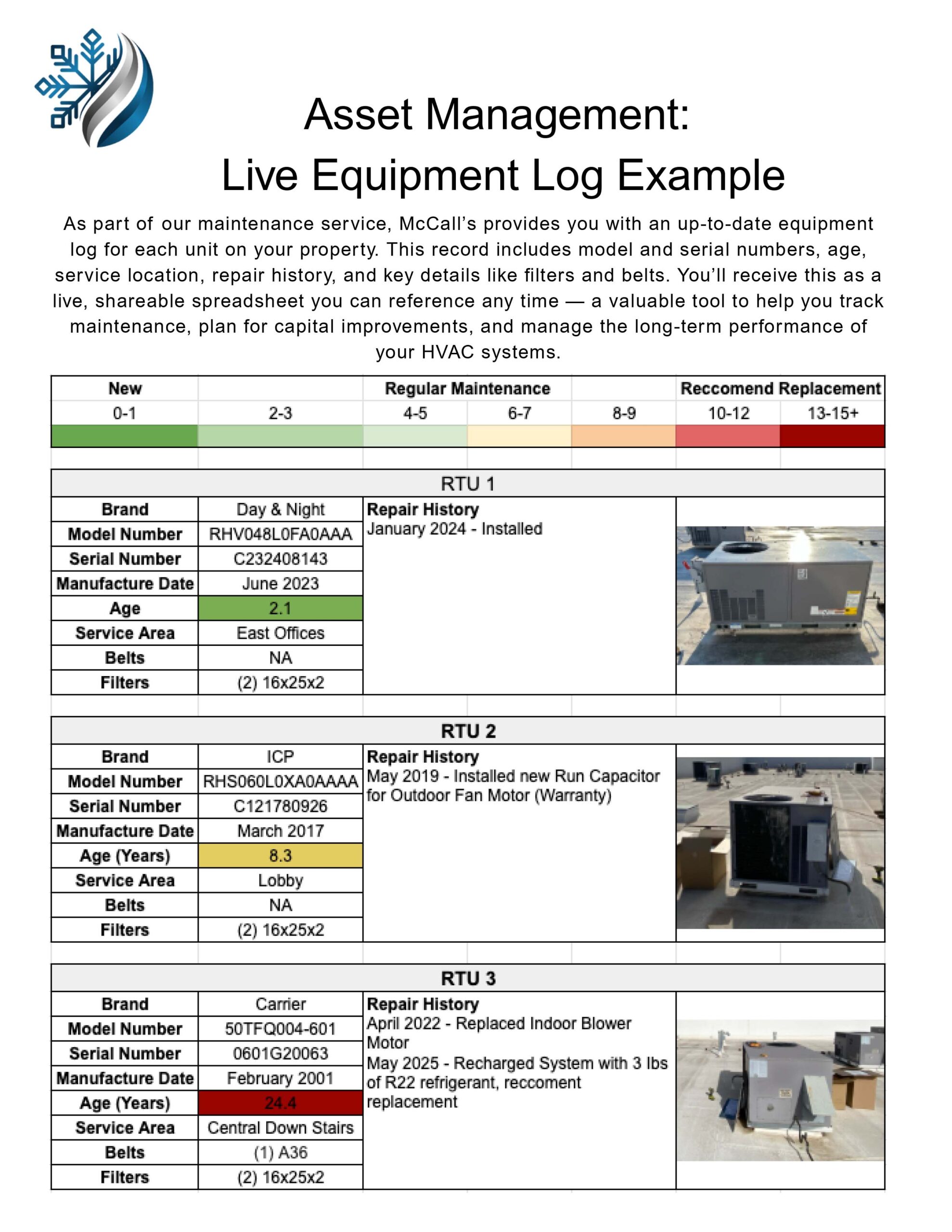

- Live Google Sheet equipment log (model, serial, filter sizes, age, location, history)

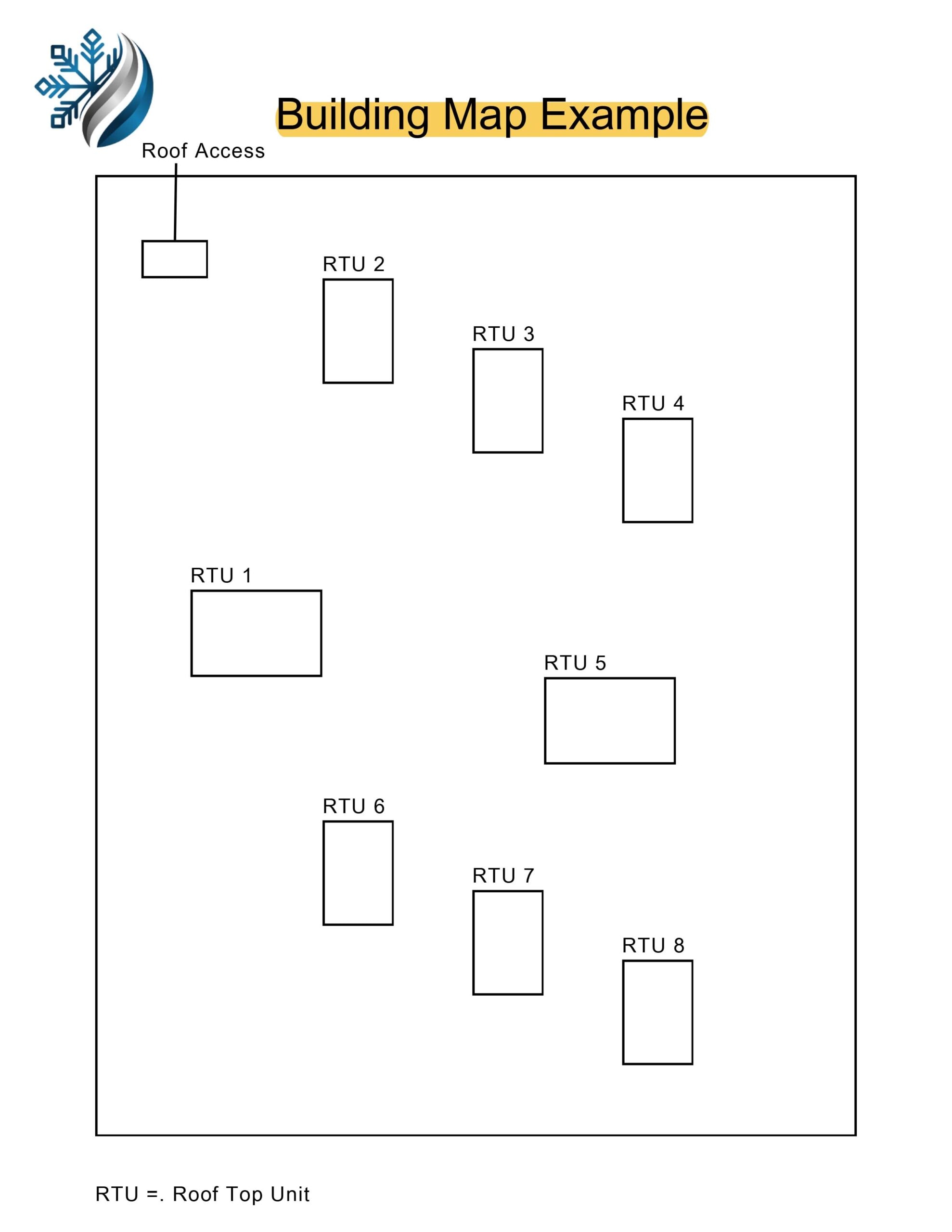

- Shared building map for easy location access

Maintenance Checklist

Inspect

- Indoor coils, ducting, circuit boards

- Disconnects, fuses, wiring connections

- Belts & pulleys (adjust if needed)

- Safety and control systems

Test

- Refrigerant pressures

- Voltage/amperage draw

- Thermostat calibration

- Reversing valve (if applicable)

- Superheat/subcooling

- Temperature split (supply/return)

Clean

- Outdoor coils

- Blower compartments (biannual)

- Electrical panel

- Flush condensate drains

- Lubricate motors/bearings (as applicable)

Replace

- Filters (Quarterly)

- Belts (Annually, if present)

- Common failure parts: 1 capacitor, contactor/relay, up to 2 fuses, and 1 lb refrigerant if needed

- NOTE - replacement of these parts are done at NO additional cost. If the part breaks during a non maintenance visit, we will replace at NO additional cost as well. This is the McCall’s difference in how we take care of our customers